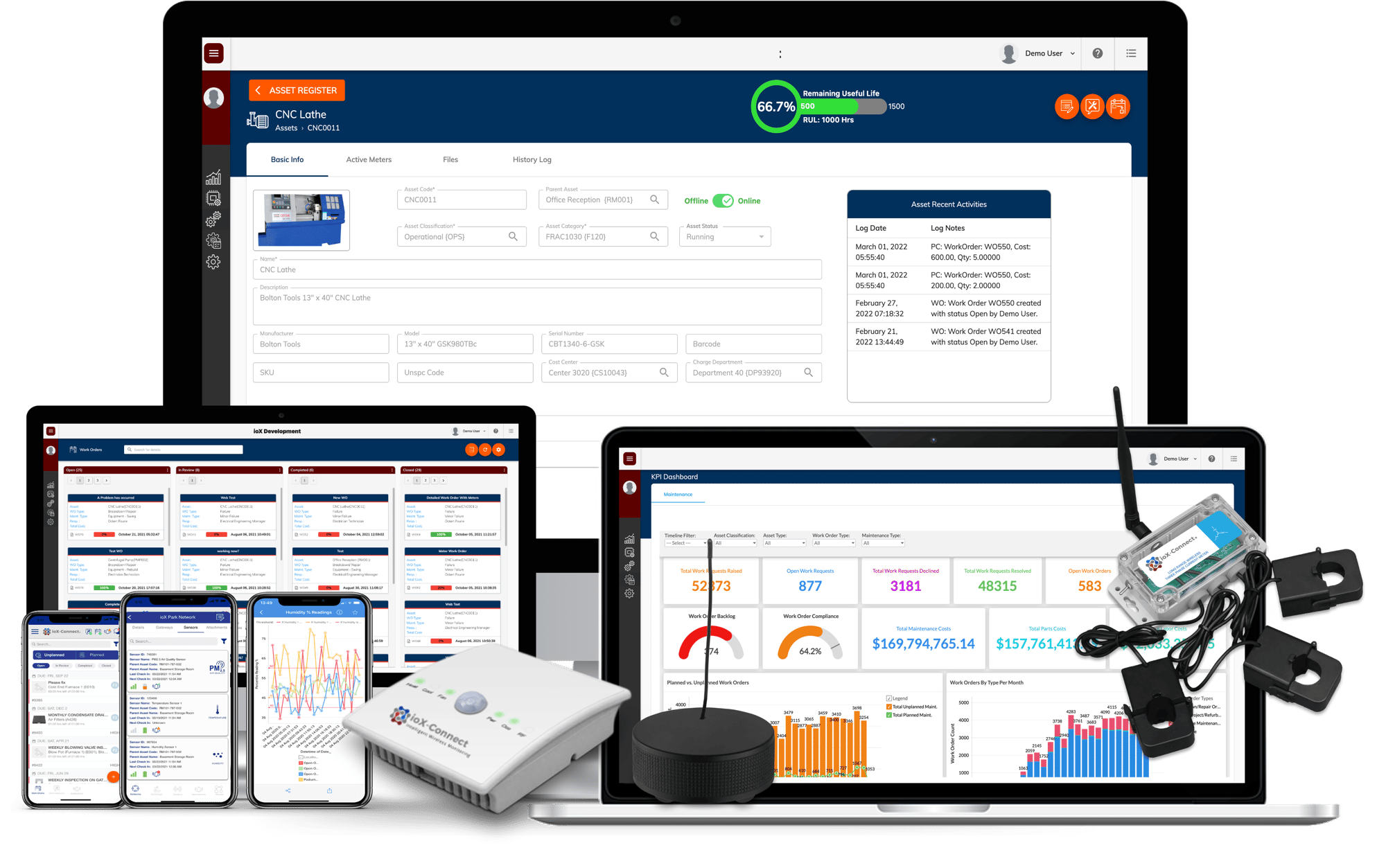

Built-in Plug & Play IoT Module

Seamless IoT Integration for Smart Maintenance Management

Unlock the full potential of your maintenance operations with ioX-CMMS’s Built-In IoT Module. Designed for plug-and-play compatibility with ioX-Connect sensors, this module enables real-time monitoring, automated alerts, and data-driven maintenance decisions. Transform your maintenance processes with seamless IoT integration to improve efficiency, reduce downtime, and enhance asset performance.

Real-Time Monitoring & Automated Alerts for Peak Efficiency

Enhance your maintenance operations with ioX-CMMS’s IoT Module, offering real-time monitoring and automated alerts for improved efficiency and asset performance.

- Plug-and-Play Integration

- Real-Time Data Collection

- Automated Maintenance

- Instant Alerts

- Trends Analysis

- Enhanced Asset Performance

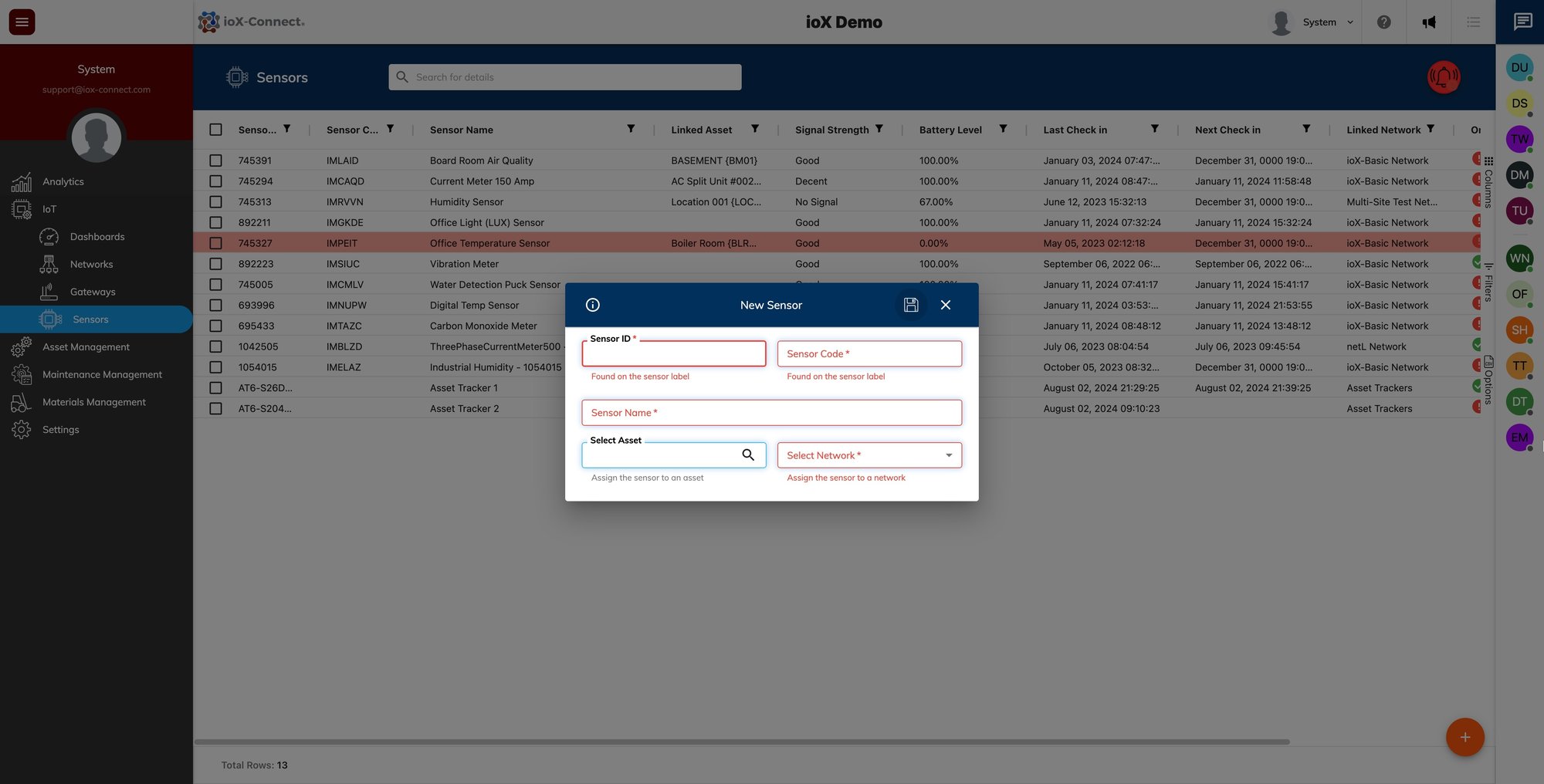

Plug-and-Play Integration with ioX-Connect Sensors

Connect ioX-Connect sensors effortlessly to your ioX-CMMS platform. Our plug-and-play setup ensures quick and hassle-free sensor integration for immediate insights and control.

- Compatible with a wide range of ioX-Connect sensors.

- No complex configuration required.

- Start monitoring in minutes with seamless connectivity.

Real-Time Data Collection

Monitor your assets in real time with continuous data collection from connected sensors. Gain instant visibility into equipment status and environmental conditions.

- Track equipment runtime hours, temperature, humidity, pressure, air quality, and more.

- Receive live data updates directly in your CMMS.

- Ensure timely maintenance decisions based on real-time insights.

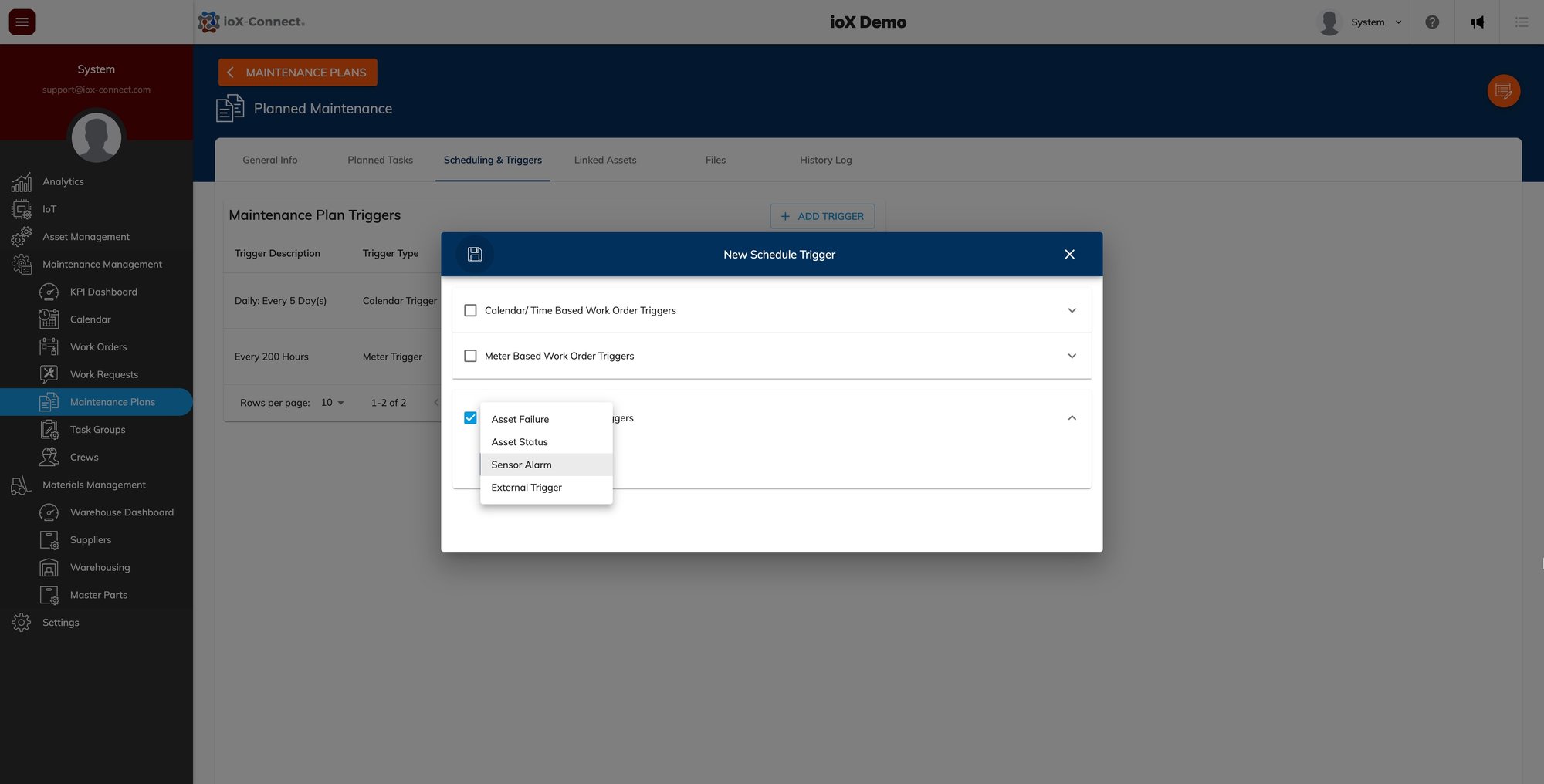

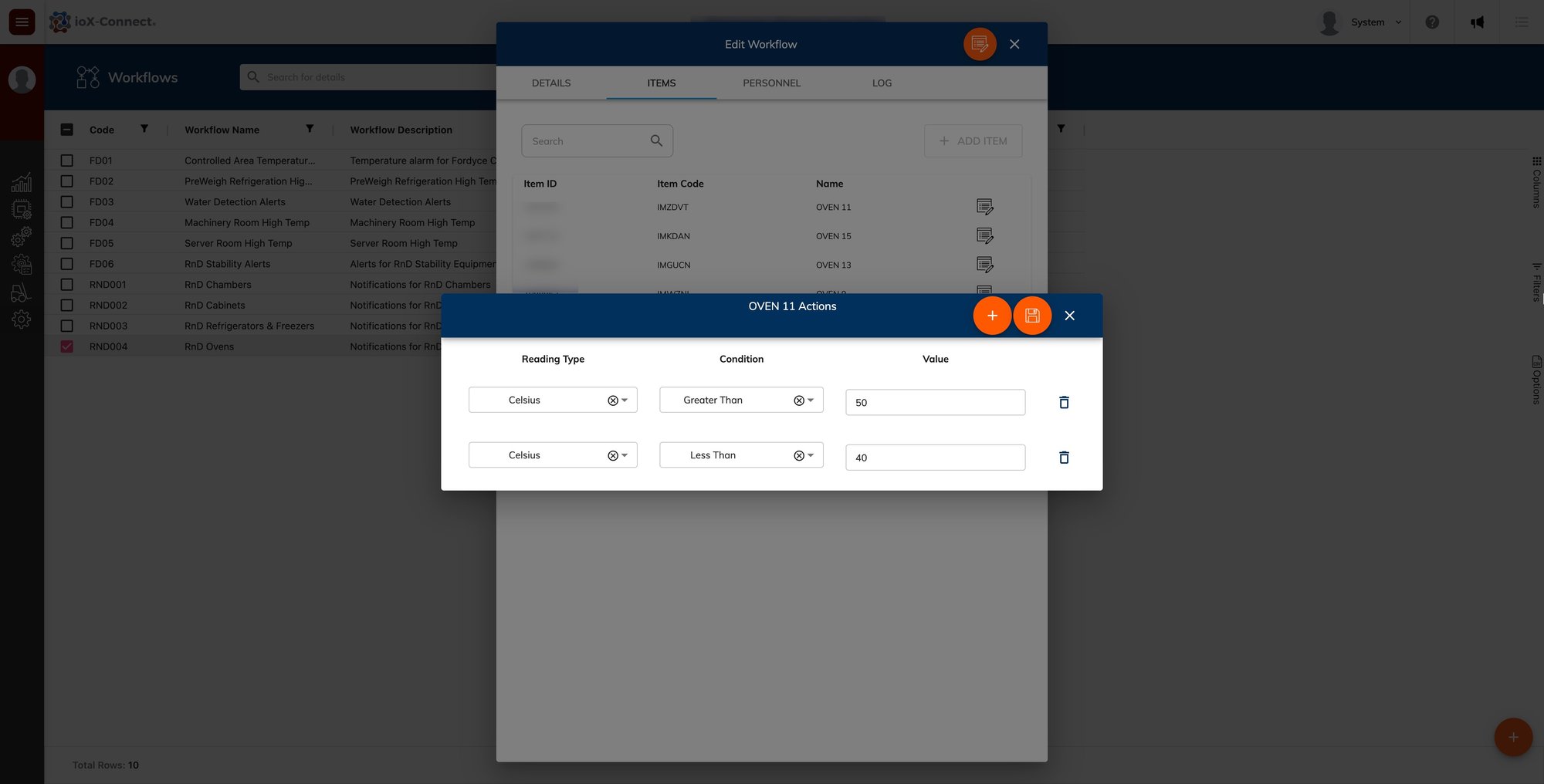

Automated Maintenance Triggers

Set up automatic work orders and alerts based on sensor data. Trigger maintenance tasks when specific conditions or thresholds are met to prevent failures and reduce downtime.

- Automate maintenance tasks based on sensor readings.

- Define thresholds for temperature, pressure, vibration, and other metrics.

- Reduce manual intervention with automated workflows.

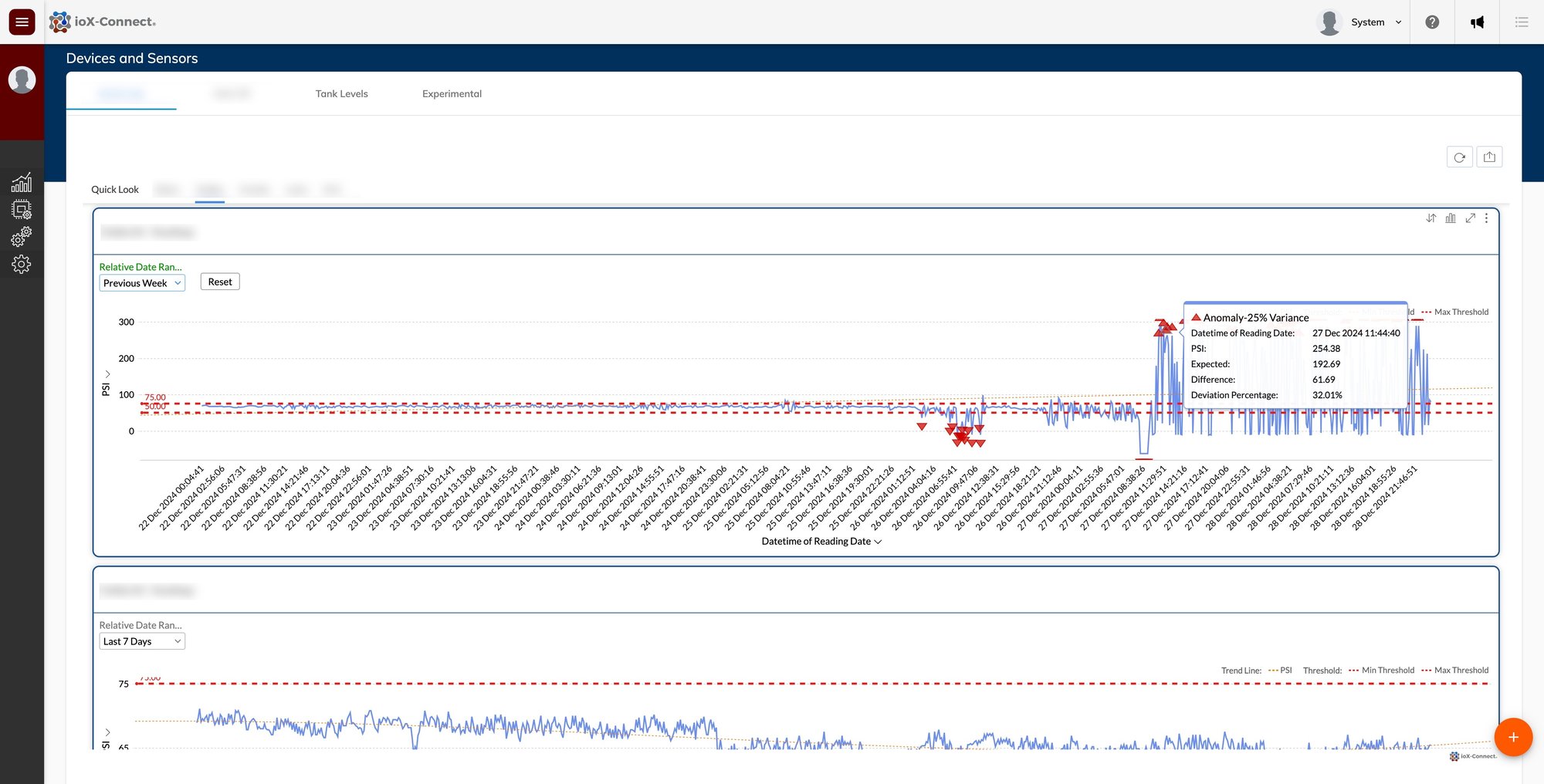

Instant Alerts and Notifications

Stay informed with instant alerts for critical events. Receive notifications via email, SMS, or in-app messages to ensure quick response to potential issues.

- Get real-time alerts for anomalies or equipment failures.

- Customize notifications for different sensors and conditions.

- Improve response times and reduce downtime.

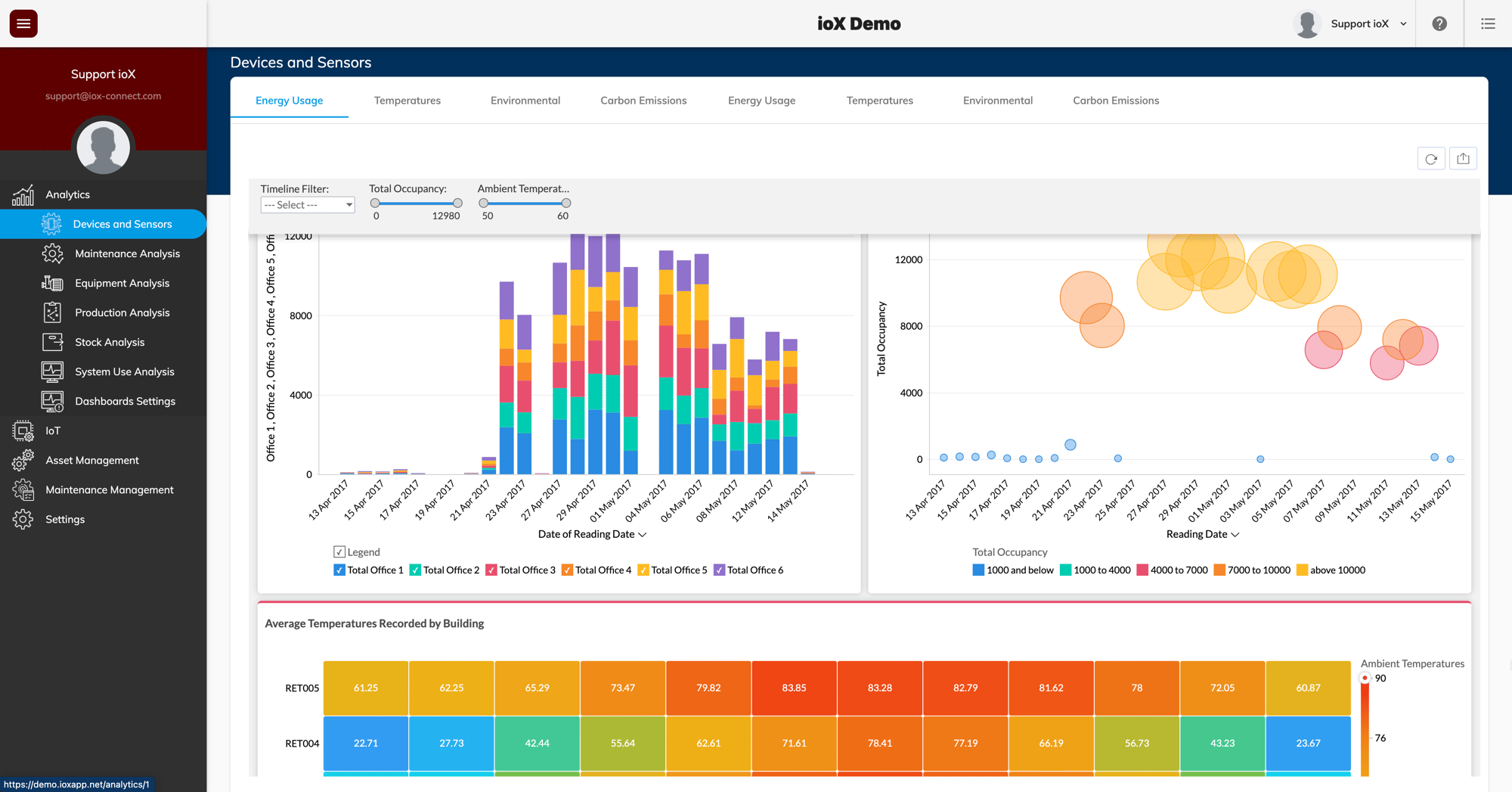

Historical Data and Trends Analysis

Analyze historical sensor data to identify trends and patterns. Use insights to optimize maintenance schedules, improve asset performance, and reduce unexpected breakdowns.

- Access historical sensor data for in-depth analysis.

- Identify recurring issues and optimize maintenance strategies.

- Make informed decisions with data-driven insights.

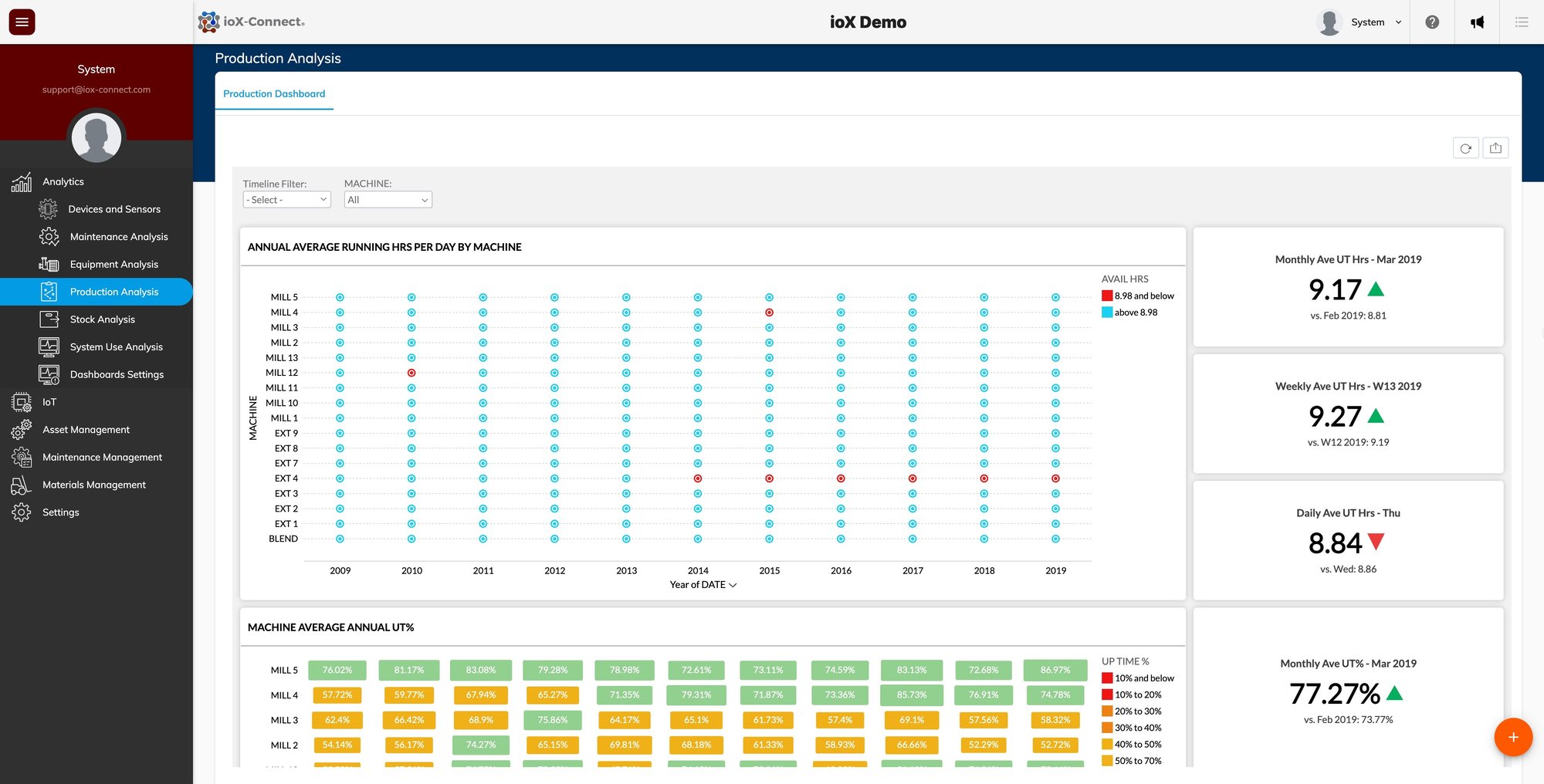

Enhanced Asset Performance

Improve the reliability and efficiency of your assets with IoT-enabled insights. Monitor asset health continuously and take proactive steps to extend equipment lifespan.

- Identify performance issues before they lead to failures.

- Optimize asset usage and maintenance frequency.

- Enhance overall equipment effectiveness (OEE).

Wireless Sensors

The ioX eco-system of 80+ sensor types detects changes in variables (such as excessive vibration, temperature, water presence, electrical current and voltages) to employ an autonomous wireless sensing solution that protects your bottom line.

ioX-Connect Asset Trackers

Designed for versatility and powered by cutting-edge connectivity, ioX-Connect's Asset Tracking devices delivers unparalleled asset tracking and monitoring across industries.

Wireless IoT Gateways

Experience the robust reliability of ioX-Connect's Cellular IoT Gateways, engineered specifically for seamless integration with ioX-Connect sensors.

Interested in Hardware as a Service (HaaS)?

Flexible financing for your technology needs

Major Fracking Company

VP Maintenance Management

"ioX-CMMS is a game-changer in the maintenance management industry. It has helped us reduce equipment downtime and optimize our manpower. Highly recommended!"

Pharmaceutical Manufacturer

Engineering Manager

"ioX-CMMS is a top-performing maintenance management solution in the market. Its innovative tools and exceptional service make it a must-have for any business."

Connected

Designed specifically for IoT and mobile applications. Integrates with sensors, meters, PLCs, SCADA, ERP, MES, and nearly all corporate systems and solutions.

Fast

ioX-CMMS is quick to implement and use, with tools enabling setup in days and work orders in hours or seconds.

Smart

Our Dashboards and Analytics excel, offering standard options for basic needs and Custom Analytics for complex requirements.

Mobile

Our iOS app enables field technicians to manage work tasks and record job details effortlessly, designed for ease of use even for beginners.

Trusted by customers across multiple industries

Frequently Asked Questions About CMMS

Have more questions about how a CMMS can transform your maintenance operations? We’re here to help! Explore our FAQs for quick answers to common questions, or feel free to reach out to our team for personalized assistance. Let us guide you toward the right solution for your business needs.

A Computerized Maintenance Management System (CMMS) is software that helps organizations manage and streamline maintenance operations. It tracks work orders, schedules preventive maintenance, monitors assets, and provides analytics to improve efficiency and reduce downtime. For a more in depth look at what is a CMMS, check out our What is a CMMS Informational Page

A CMMS centralizes maintenance data, allowing users to create work orders, schedule tasks, track asset performance, and access real-time insights. Technicians can update task statuses, log maintenance activities, and access manuals or checklists, ensuring smooth operations.

A CMMS improves maintenance efficiency, reduces unplanned downtime, extends asset lifecycles, and enhances compliance. It also provides data-driven insights for better decision-making and streamlines communication between teams.

CMMS software is used by maintenance managers, technicians, and facility managers across industries such as manufacturing, healthcare, hospitality, utilities, and logistics to manage equipment and facilities effectively.

While both systems manage assets, a CMMS focuses on maintenance operations, such as work orders and preventive maintenance. Enterprise Asset Management (EAM) provides broader asset lifecycle management, including procurement, inventory, and financials.

Yes, a CMMS like ioX-CMMS supports multi-site management, allowing users to track assets, work orders, and maintenance schedules across multiple facilities from a single platform, ensuring data segregation and efficient management.

A CMMS automates preventive maintenance scheduling based on time, usage, or condition triggers. This ensures timely inspections and repairs, reducing breakdowns and extending equipment lifespans.

Modern CMMS platforms, like ioX-CMMS, are designed with an intuitive interface, making them easy to use for technicians and managers alike. Mobile accessibility further enhances usability, allowing updates from anywhere.

A CMMS provides detailed reports on work order history, asset performance, maintenance costs, technician productivity, and compliance metrics. These insights help optimize maintenance strategies and improve ROI.

To choose the best CMMS, consider your organization's size, industry, and specific needs. Look for features like work order management, preventive maintenance, multi-site support, mobile access, and robust reporting. A scalable and customizable solution like ioX-CMMS is ideal for businesses of all sizes.

Our Products and Services?

We're here to help, do not hesitate to reach out to us by scheduling a quick call with one of our representatives.

Contact Us

Our customer service team is ready to assist you in exploring our offerings tailored to your business objectives.